Ba Na cable car started construction in 2008, undergoing a difficult construction process because of the difficult terrain and lack of construction equipment. With determination and perseverance, after 400 days of awakening Ba Na mountains and forests, Ba Na Hills cable car route has officially operated successfully and marked with 4 Guinness records. For details about the Ba Na Hills history and construction process of Ba Na cable car, please follow in the content below.

Overview of Ba Na Hills cable car

Ba Na Hills cable car was invested by Sun Group with a cost of nearly 300 billion VND – the largest cable car investment in Vietnam up to now. Not only astonishing in terms of investment costs, the construction of Ba Na Hills cable car also impresses with the participation of the world’s leading cable car and cabin manufacturer, Doppelmayr and CWA.

Doppelmayr Group was established in 1893, is the unit behind the success of the construction of pillars and cable cars Ba Na and a series of “mobile high” projects such as:

The world’s first cable car in Bratislava

Mandalay Bay Tram – the first cable car in Las Vegas

The world’s first 3-second cable car in France

The first urban cable car in England

The 3-wire cable car connects Mount Whistler and Blackcomb in Canada

Ski lift in Zürs am Arlberg

Von Roll Cable Car

Besides, CWA company is the unit behind the system of nearly 100 safety cabins of Ba Na Hills cable car. The company was founded in 1939 and produces more than 2,000 cabins per year for the global market. Cabin quality has been proven by safe, durable constructions such as Titlisbergbahnen in Engelberg Switzerland, or the world’s largest cabin with a capacity of 230 people per cabin at Sun World Ha Long Vietnam.

For those who don’t know when was Ba Na Hills built? Ba Na Hills cable car was started construction in 03/2008 and officially put into operation on 25/03/2009.

Ba Na cable car structure has a total length of 5,771.61m, including 22 pillars, 94 cabins designed including 6 sides of tempered glass.

The smallest cabin accommodates 6 – 8 people while the largest cabin accommodates up to 30 – 35 people.

The operating speed is 6m / s, each cable lasts about 15 minutes, the service capacity is 6,5000 passengers / hour.

Up to now, Ba Na Hills cable car has 6 cable car routes as follows:

Hoi An Railway Station – Marseille Station

Bordeaux Station- Louvre Station

Champa Station – Taiga Station

Fairy Hair Waterfall Station – L’Indochine Station

Suoi Mo Station – Ba Na Railway Station

Debay Chicken – Mornin Chicken

The above impressive figures of Ba Na Hills cable car come from an extremely difficult and difficult construction process. To better understand, let’s learn about the Ba Na Hills history in the next section.

Actual narration of the construction of Ba Na Hills cable car

The process of building Ba Na cable car started from anxiety and skepticism about a cable project across the forest when the measurement technology was rudimentary and inadequate. After a period of survey and a series of arduous and hard construction days, Ba Na cable car has become one of the most impressive works for Vietnam’s tourism industry. The Ba Na Hills historys of building Ba Na cable car is basically divided into 3 stages:

Decision Stage: One Hour, in One Day October 2007

Survey and design phase: Within 3 months from 10/2007.

Construction and completion phase: More than 1 year from 03/2008 to 25/03/2009.

Decision Stage – Within 1 Hour

In October 2007, former Director of Ba Na Cable Car Joint Stock Company (belonging to Sun World block of Sun Group) – Mr. Vu Huy Thang and the Board of Directors of Da Nang City visited Ba Na. The pristine scenery along Ba Na Street makes Mr. Thang lose confidence and has no intention of investing in building a cable car there. However, the leadership of Da Nang City has said that Ba Na is the youngest daughter of Da Nang and “begs” to marry Sun Group. The leaders of Sun Group have instructed the survey team to be determined to implement the project.

After receiving difficult questions from Sun Group and surveying the actual site, Mr. Vu Huy Thang, despite many concerns in his heart, still made a decision to do this project within 1 hour. It was this decision that helped Mr. Vu Huy Thang and the construction team become gods, construct a lifelong cable car project, contributing to helping Danang tourism make a breakthrough.

With boldness and a little “dose”, the project team talked to the equipment supplier from Austria. The manufacturer of the Doppelmayr cable car claims that the cable car after completion can reach world records for length and height, but a one-year limit is impossible. Doppelmayr proposed using helicopters to deliver all materials, concrete, steel pillars to the foundation sites. However, Ba Na’s specific conditions do not allow this option to be implemented. How to handle it up to this point is still open and must wait until the survey stage to have an official answer.

Survey and design phase – 3 months of difficult start

After the investment plan was approved, on 03/09/2007, the project team consisting of 10 engineers of Ba Na Cable Car JSC entered the forest, headed to the top of Chua Mountain to carry out topographic survey, cable design, measurement and drilling within 3 months. Doppelmayr’s cable car experts also flew from Austria to Da Nang to learn about the site before starting to produce equipment and components.

During this survey, the team had to ensure that the cable car landmarks were absolutely accurate because Doppelmayr experts allowed an error of less than 1cm.

During the three months of work, the survey team faced many dangers in the sacred forest of poisonous water, even flash floods because it was the rainy season. Mr. Thang recalled: “I remember once going to survey, in the evening the brothers often stuck hammocks near the stream, there was a very big rock in the stream, the brothers stuck hammocks there. We were accompanied by a local guide, he was very knowledgeable about Ba Na. At night, the brothers were sleeping, and he shouted, “Run, flood!” The next morning, I came back, I didn’t see the bowl of blanket chopsticks…”

In the survey team was “veteran” Tran Tinh, who witnessed all the huge obstacles on the way to pull the cable car to Ba Na peak. Referring to that difficult but equally glorious past, Mr. Tinh shared: “At that time, I had just finished the cable crossing the sea in Nha Trang, so when I entered Da Nang, I was very excited. However, as soon as she touched Ba Na’s door, fear came over. Looking at the forest is gloomy, I told them stop, I didn’t do it, it’s too miserable to come out here, the forest is so roaring”

To route the 22 backbone pillars of the No. 1 cable car, the survey team was forced to cut through the forest to find a path, passing a primeval forest with intertwined vines above, below which wild pineapple trees blocked the path, around the easterly wind rushing to bone-chilling cold. The survey team walked, using machetes and hoes to create roads, with scars on their hands from the greenery.

Difficulties piled up when the survey team advanced to the mountain in the rainy season, the mushy and slippery forest soil made the footsteps heavy, not only that, but orphaned maple stones came out, rolling down the bottom with steep edges with a slope of up to 30%. At this time, the survey team could only gouge into the mountain rock to climb, the whole body was drenched in sweat, mountain dew and forest rain.

Another member of the survey team, Mr. Hoang Van Thieu – Deputy Director of Ba Na Cable Car Service Joint Stock Company, said: On September 3, 2007, the group started their journey with a truck carrying 2 computer rigs, 2 motorbikes, some tables and chairs and 30 million VND. He recalled that each day they started their mornings as soldiers, distributing food to each person who entered the line. Each “soldier” went to the forest with a backpack with water, dry food, shrimp noodles, snakebite medicine and squeeze medicine. It can be seen that, although the task is laborious, the nutrition of the survey team is very inadequate.

Moving is difficult, eating poorly is not enough, the sleep of the survey group is not much better. The survey team had to wear specialized hammocks to sleep, and at night the sound of howling apes, insects, the sound of the wind hissing and the fear of green snakes gave the men chills, unable to sleep.

Not only encountered many difficulties in the process of moving and measuring, the survey team also had to solve the problem of only 1cm error of the cable car routing line given by Doppelmayr engineers. Former surveying engineer Trinh Van Ha shared: “With the conditions of steep terrain, large vertical slope, dense forests, plus facilities in 2007 in Vietnam, the requirements of foreign experts are almost impossible.”

At that time, only 3 GPS machines of Military Region V could support routing with the allowed error. Therefore, the most effective solution at this time is still to rely on human power combined with measuring and calculating on the chart. The survey team was divided into two capes, nose 1 measured from the foot of the mountain, nose 2 measured from the top of the mountain, however, when the two sides met, the difference was up to 50m. The next solution is to combine universal measurement methods and use satellite navigation. The measurement journey continued until, in early 2008, the routing of the backbone for cable car line 1 was officially completed.

Construction and completion phase – 1 arduous but emotional year

After 3 months, the survey team understood the terrain and climate of Ba Na mountain. However, the weather at the time of construction was in the rainy season, fog and cold wind made it impossible for the construction team to determine the direction to build. The 22 foundation dumping points are all located deep in the jungle, so all means of transport cannot be used. The most feasible option then is to carry sand, stone, cement, yeast drill up the mountain road to the gathering point.

Mr. Tran Van Minh, a member of the construction team said: “Sometimes, carrying stones and stones, machinery to the bottle of both shoulders, sweat is always profuse like a bath. We even hired the S’tieng people to work with us because only they knew the forest and the mountains.”

Not only Mr. Minh haunts the days of carrying heavy loads, engineer Pham Khac Hang also shared: “To take the machine away, we have to disassemble each component and then carry the set. From pillar to pillar it takes up to 3.4 days to move. Ba Na was in the rainy season again. Walking, slipping and falling, rolling with mud.”

With human power alone, bulky machinery could not reach the pillar pits and the workers had to use their bare hands to dig foundations and level them with the most rudimentary tools, hoes and shovels. According to Mr. Nguyen Huu Tan – technical staff of cable car route No. 1: Each foundation pit is nearly 10m deep, 15m horizontal and vertical. Every time they dig more than 1m, they come across huge stumps as big as 10 people hugging and hard enough to bend the shovel blade, or orphan rocks so big and hard that the drill can’t do anything, floating in the ground.

In addition to terrain challenges, weather also greatly affects the construction schedule. Heavy rain not only lashed the faces in pain, making the workers unable to open their eyes, but also dragged rocks rolling furiously towards the camps, endangering them. Harsh weather also hindered food supply, the construction team only had to find crabs and catch fish to survive.

A series of difficulties beset the construction team to find another more feasible option to keep up with the schedule, which is to create the service cable themselves because they cannot use helicopters and cut down trees to pave the road. To save costs, instead of erecting support poles as suggested by experts from Austria, the construction team fixed each section of the cable loaded onto the forest tree trunks, then used hoists and electric winches to transfer materials to the foundation pit. This initiative amazed the Austrian partner to the point of exclaiming “incredible!” and was applied to many projects with similar terrain features.

The service road option is superior to the previous one but also requires a large amount of manpower to pull bundles of cables weighing up to 1 ton through the mountains. In the beginning, on average, 3 months the construction team pulled a cable stage. Then, thanks to the cooperation of 2 other contractors, the progress was accelerated. In June 2008, the fully man-powered service cable line was officially operated throughout the route where the cable car pillars are located. As a result, large machines and thousands of tons of materials were quickly transported into the foundations, speeding up the completion of the Ba Na Hills cable car.

After more than 400 days of survey and construction, with countless difficulties in the task of completing the cable car as well as preserving the forest ecosystem, the people of Da Nang and the construction team finally have the right to be proud of one of the greatest cable car projects in the history of Vietnam tourism.

On 25/03/2009, Ba Na – Suoi Mo cable car system was officially operated, bringing visitors to Ba Na Hills. The people of Da Nang are extremely happy with this record project because they know that this nearly 6000m long cable car will help tourism prosper, improve the economy of local people, the face of the city as well as the stature of Vietnam in the eyes of international friends. The proof is that Ba Na cable car has set up to 4 Guinness World Records and contributed greatly to the development of Da Nang tourism.

Record “broken” by Ba Na Hills cable car

After being built and put into operation, on 29/3/2013, Ba Na Hills cable car consecutively achieved 4 Guinness World Records. This is also the only cable car to set 4 Guinness World Records simultaneously:

The longest single-rope cable car in the world with a length of 5,771.61m.

The cable car has the highest difference between departure and arrival stations in the world of 1,368.93m.

The length of the world’s longest unextended cable is 11,587m.

The world’s heaviest cable coil at 141.24 tons.

On 28/11/2019, Sun World Ba Na Hills was honored with the award “World’s Leading Cable Car System” in the World Travel Awards. This is really a proud achievement because Ba Na Hills cable car has surpassed equally spectacular contenders such as BondinhoPao de Acuca cable car (Brazil), Mi Teleferico cable car (La Paz, Bolivia); cable car Peak 2 Peak (Canada); Skyline Queestown cable car (New Zealand) …

In addition to the records and awards representing international recognition, Ba Na Hills cable car has also become a factor contributing to the development of tourism of Da Nang City. In the decade from 2009, the number of visitors to Da Nang grew by 463%. in which, visitors to Ba Na Hills increased more than 160 times (from 2,079,758 to 13,300,000 visitors) and Da Nang’s tourism revenue has increased 15 times between 2009 – 2018. Particularly in the first 10 months of 2023, the total number of visitors to Ba Na Hills is 3,134,897 visitors, accounting for 49% of the total number of visitors to Da Nang.

It can be seen that the Ba Na Hills historys shows the spirit of overcoming difficulties and the strong will of the team behind Ba Na Hills project. With the dream of awakening the potential of Danang tourism, Sun World has invested wholeheartedly in material terms while the survey and construction team traded time and health to stay on Ba Na mountain for 400 days, until the Ba Na Hills cable car miracle project is completed. Thanks to the cable car, Danang tourism in general and Ba Na Hills tourism in particular have made incredible strides.

Sitting on the Ba Na Hills cable car, visitors can admire the immense forest leading up the mountain below the cable car, the panoramic mountain and the “foreground” beauty on the top of Ba Na mountain 1487 m above sea level. Visitors wishing to visit Ba Na by cable car please find out more information at:

Website: https://banahills.sunworld.vn/

Fanpage: https://facebook.com/SunWorldBaNaHills

Hotline: + 84 (0) 905 766 777

![[HOT] HOAI LINH AND DAUGHTER SAM GO IN FOR MYSTERIOUS CHASE AFTER VANISH](https://banahills.sunworld.vn/wp-content/uploads/2018/08/1-300x200.jpg)

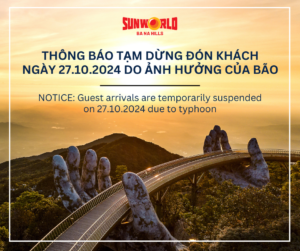

![[ANNOUNCEMENT] SUN WORLD BA NA HILLS IS TEMPORARILY CLOSED DUE TO TYPHOON NORU’S THREAT](https://banahills.sunworld.vn/wp-content/uploads/2022/09/MicrosoftTeams-image-46-300x300.jpg)

![[ANNOUNCEMENT] BA NA BY NIGHT CHANGES THE BUS PICK UP POINT](https://banahills.sunworld.vn/wp-content/uploads/2023/10/update-300x300.jpg)

![[NOTICE]_Temporary Suspension of Mountain Train Route 2 from May 9th to May 15th, 2024](https://banahills.sunworld.vn/wp-content/uploads/2024/05/THONG-BAO-TAM-DUNG-HOAT-DONG-TUYEN-TAU-HOA-LEO-NUI-SO-2-DEN-LAU-DAI-MAT-TRANG-TU-1-300x300.png)

![[Announcement] Alpine Coaster 2 Reopens From 01/06/2024](https://banahills.sunworld.vn/wp-content/uploads/2024/06/Alpine-Coaster-2-Reopens-1-1-300x300.png)

![[NOTICE] Sun World Ba Na Hills opens normally from 19.09.2024](https://banahills.sunworld.vn/wp-content/uploads/2024/09/THONG-BAO-TAM-DUNG-3-300x251.png)

![[NOTICE] Loyalty cards will officially no longer be available for purchase from October 02, 2024](https://banahills.sunworld.vn/wp-content/uploads/2024/10/Thong-bao-300x300.png)

![[ANNOUNCEMENT] DAILY OPERATION SCHEDULE AT SUN WORLD BA NA HILLS](https://banahills.sunworld.vn/wp-content/uploads/2025/03/290627370_5068557996607013_8836115917887277868_n-300x300.jpg)